Mechanical Engineering Technology – Industrial (Fast Track)

Centennial College’s Mechanical Engineering Technology – Industrial (Fast-Track) program allows qualified mechanical engineering college or university graduates direct entry into year two (semester three) of this program so they may receive their Technology advanced diploma in two years (four semesters).

Duration

2 years

Starting Date

January, September

Tuition Fee

$17,206

Location

Blended (Toronto, Canada & Online)

About the program

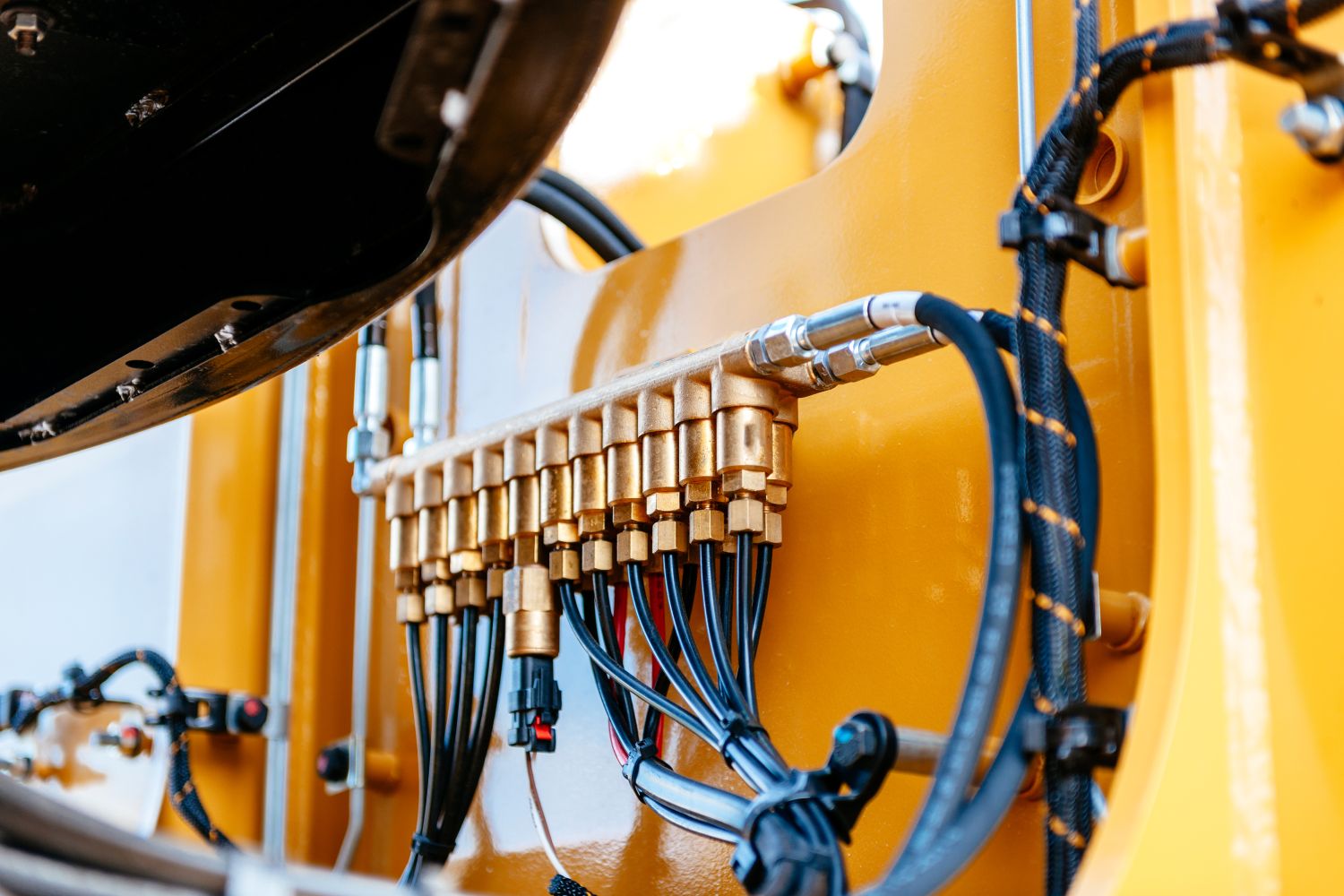

This advanced diploma program’s Mechanical Engineering Technology – Industrial (Fast-Track) courses from Centennial College offer both engineering theory and practice while emphasizing the design and development of various mechanical devices and equipment. This results in a thorough grounding in engineering sciences and skills, including intermediate to advanced computer-assisted design and manufacturing as used in the industry.

You spend about one quarter of the program on project work that simulates workplace assignments. You are also required to relate classroom theory to the actual design, manufacture and testing of mechanical systems.

Career Prospects

Career Outlook

- Manufacturing supervisor

- Junior engineer

- Mechanical tester

- Quality controller

- Facility planner

- Process engineer

- Lab/CMM technician

- Junior project manager.